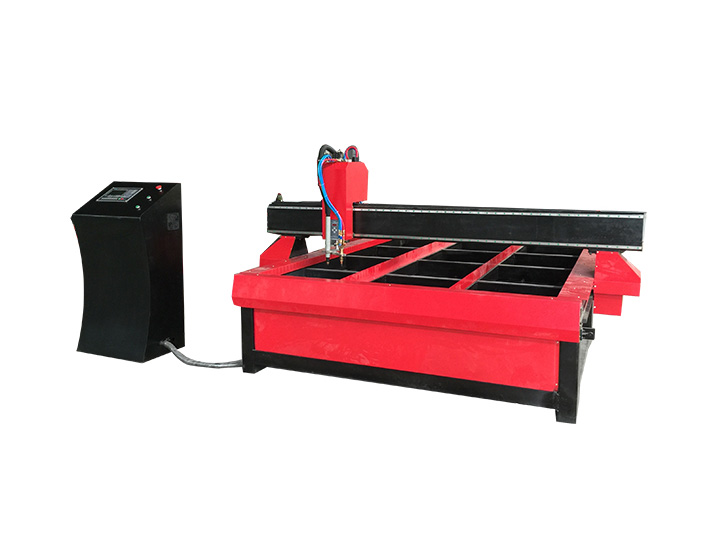

METAL PLASMA CUTTER WITH FLAME CUTTING TORCH STP1530

Metal plasma cutter with plasma and flame torch for sale, the metal cutting thickness less than 10mm, the plasma torch is the best choose, the metal cutting thickness more than 10mm, the flame torch is the best choose.

Metal plasma cutter with flame cutting torch advantage:

- Welded lathe bed of thick profiled steel, more solid and stable.

- Perfect lathe table design, 10mm steel plates fixed on lathe table covered by cast sheath.The level difference of platform remains in 0-1.5mm.

- Advanced material inclined discharging design.

- CNC system configuration high, automatic arc, stable performance, the success rate of 99% arc.

- Support Fastcam, ARTCAM, Type3 software such as the standard G code path generated file can also be read by software conversion software such ad AUTOCAD generated DXF formats. U disk exchange control system processing files, easy to operate.

- Plasma torch power supply and supporting all famous brands, a number of national patents by the manufacturers.

Application of metal plasma cutter with flame cutting torch :

- Suitable material Cutting on Iron Plate, Aluminum sheet, Galvanized Sheet, Stainless,Titanium plates etc.

- Application industries Case shell of mechanical and electrical products processing,advertising signages,process decoration, black smith gardens, automobile, shipbuilding, electrical accessories cutting and processing ,welding industry etc

Features of metal plasma cutter with flame cutting torch :

- Gantry structure, perfect bearing capability.The machines’ body is strong, rigid, high precision, reliable and durable.

- Double cutting torch:plasma cutting torch and flame cutting torch(Oxygen),suitable for cutting steel board of different thickness

- Adopt well known plasma power Hypertherm supply and cutting torch.

- Cutting edge is small and smooth ,without any drop outs,thickness for metal cutting is up to 50mm.

- With Arc voltage Auto Height-adjusting Device, arcing success rate over 99% and can protect cutting torch from damage, increase cutting quality.

- Adopts Imported high-precision Hiwin Linear guide rails, smooth movement, to ensure that the machine tools high-precision.

- Drive gear and rack ,customized from professional manufacturer, is surface processed by cemented quenching, which can prolong machine’s using life.

- Servo drive system is available,which with features of function detecting ,high running precision, wide speed range and short speed up time.

- Excellent performance on cutting illuminated letters for advertising and channel letters on metal surface board.

- Designer perfectly, select the best machine accessories, to minimize the failure rate preferred.

Metal Plasma Cutter Video

Technicial parameters of metal plasma cutter with flame cutting torch :

| No. |

Item |

Specification |

|

1 |

Machine Overall Width |

2000 mm |

|

2 |

Machine Overall Length |

3500 mm |

|

3 |

Effective Cutting Width |

1500 mm |

|

4 |

Effective Cutting Length |

3000 mm |

|

5 |

Plasma Maximum Cutting Thickness |

According Plasma Power |

|

6 |

Positioning Speed |

0-12000 mm/min |

|

7 |

Positioning Accuracy |

±0.2 mm/10m |

|

8 |

Maximum Cutting Speed |

4000 mm/min |

|

9 |

Torch Vertical Movement |

50 mm |

|

10 |

Lifting Regulating Accuracy |

±0.5 mm |

|

11 |

Plasma Torch Station |

1 Set |

|

12 |

Plasma Torch |

1 Set |

|

14 |

Plasma Torch Anti-Collision |

1 Set |

|

15 |

Plasma Arc Voltage Height Adjusting |

1 Set |

|

17 |

Drive Mode |

Dual-Side |

|

18 |

Driving Motor |

Step Motor |

|

19 |

Operation Panel Language |

English |

Sample of Metal Plasma Cutter